PVD aluminium vacuum coating metallizing machine

- Continuous Magnetron coating Production Line

- Vacuum Coating Equipment

- Large Multi-arc ion vacuum coating equipment

- Vacuum Evaporation Coating Equipment

- Vacuum multi-arc ion coating equipment

- Vacuum magnetron sputtering coating equipment

- Vacuum intermediate frequency coating equipment

- DLC & Tools and Mould Vacuum coating equipment

- Coating Service

- PVD Vacuum System for Glass Products

- Accessories

- Cleaning Machines

- Ungrouped

- Name:

- Lincoln Li

- Tel:

86-15335326363

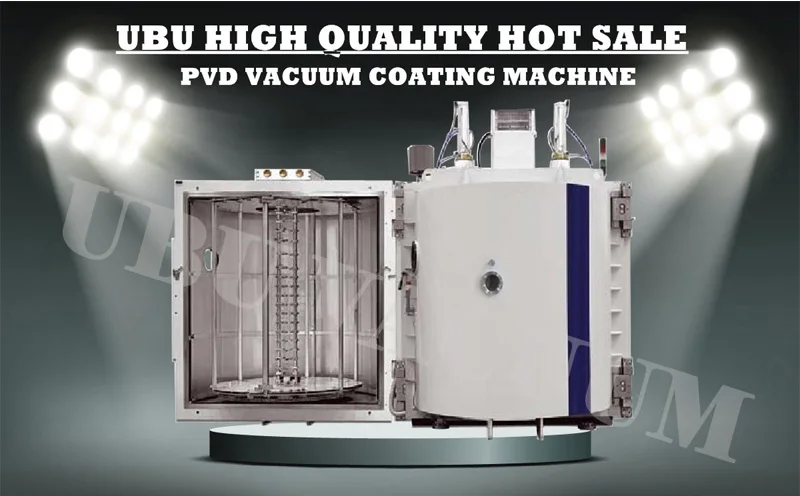

PVD aluminium vacuum coating metallizing machine

| Categories | Vacuum Evaporation Coating Equipment |

|---|---|

| Brand | UBU PVD coating machines Manufacturer |

| Model | ZF |

| Substrate: | Al, Ti, Ni, Ag, Au, Cr |

| Ertification: | ISO9001,CE, SGS |

| Update Time | Apr 24,2025 |

Aluminium coating pvd vacuum metallizing machine

Aluminium coating pvd vacuum metallizing machine is a hightech environmental

friendly product for metal, glass and ceramic products surface coating. After coating

by this machine can improve the workpieces’ hardness, wear resistance, corrosion

resistance etc..The machine itself has many advantages such as quick pumping

speed, stable vacuum environment, large load capacity and uniform coating film.

Model | ZF-1000 | ZF-1200 | ZF-1400 | ZF-1600 | ZF-1800 | ZF-2000 |

Vacuum chamber size | D1000×H 1200mm | D1200×H 1500mm | D1400×H 1600mm | D1600×H 1800mm | D1800×H 2000mm | D2000×H 2200mm |

Power supply | Resistance evaporation power supply | |||||

Vacuum chamber material | SS304 superior stainless steel or superior carbon steel | |||||

Vacuum chamber structure | Vertical single/double door, back vacuum acquisition system | |||||

Ultimate vacuum | Better than 8.0x10-4Pa (no-load), leak rate1h≤0.6Pa | |||||

Pumping speed | From atmosphere to 6.7×10-3Pa spend 8~15min (no-load) | |||||

Evaporation power | 10KW | 15KW | 20KW | 20KW | 25KW | 35KW |

Total power | 25KW | 40KW | 60KW | 65KW | 85KW | 95KW |

Vacuum system | Diffusion pump + roots pump + rotary vane pump + holding pump (can be adjusted) | |||||

Measurement system | Use automatic digital display vacuum gauge | |||||

Intake system | Flow controller can be optional and with automatic control, also can be shifted between manual and automatic | |||||

Rotation mode | Frequency stepless | |||||

Cooling system | Water-cooling circulatory system,cooling water tower or industrial cooling water machine is also needed (supplied by customer) | |||||

Control mode | Manual or PLC + touch screen, can achieve automatic, manual and semi-automatic control | |||||

Alarm and protection | Water pressure alarm, atmosphere pressure alarm, over current protection, related protective measures and electrical interlock functions. | |||||

Other data | Water pressure≥0.2MPa, water temperature≤25℃, atmosphere pressure 0.5-0.8MPa | |||||

Remark | Specific configuration size can be designed according to customer requirements. Can be equipped with magnetron sputtering power supply and intermediate frequency power supply. Customizable vacuum chamber size range is D 500-3000mm, H: 500-3000mm. | |||||

Package : Wooden case

Transportation : By sea

Warranty : 12 months

Engineers available to service machinery overseas

Qingdao UBU Vacuum Equipment Co.,Ltd. is a high-tech enterprise which is specialized in engaging in researching, manufacturing and marketing various kinds of vacuum coating equipment, and these vacuum application equipment provide a powerful technical support and after-sales service for all kinds of famous enterprises both at home and abroad.

Our company has had 9 main coating equipment up to now, including Multiple arc plasma vacuum coating machine, Magnetic sputtering vacuum coating machine, Multiple functional intermediate frequency vacuum coating machine, Evaporation vacuum coating machine, Automatic optical coating equipment, Vacuum roll coating machine, DLC vacuum coating machine, UV lacquer curing system and Continuous magnetic sputtering vacuum coating line. In addition, we also provide services of professional PVD coating services according to customer’s different requirements, supplying related accessories and old machine’s updating, helping solving customer’s various questions and making all the customers satisfied.

Our company is founded on the idea of "The user is supreme, strives for perfection" , adhering to the "high quality, high efficiency, low energy consumption" development strategy. No matter the turn-key project, or one-to-one professional service policy will provide the omni bearing, multilevel and high field for the general customers high quality service. Our company will continue to make contributions to advancing the world standard of vacuum application equipment, hoping to cooperate with all customers to create new brilliant future.

1, Do you a manufacture or a trading company ?

We are a professional manufacture, making many kinds of PVD coating machines and related accessories. Our company is located in Qingdao, China, which covers more than 10000 square

meters , and has over hundred staff, including R&D team, production team, marketing team and

after- sale service team.

2, Do you have any quality certificate of your coating machine ?

Our machine has CE, SGS, IS9001 quality certificate, and also our machine has good reputation among our customers.

3, How can we operate vacuum coating machine ? Is this machine easy to use and maintainance ?

We will dispatch 1~2 technicists to the customer's factory to install and debug the machine, as well as training customer how to coat their products with different colors and how to maintain the machine within 7 days after the machine being arrived at customer's company.

4, In order to provide you suitable machine ,pls tell us some information ,thank you

a, What is your products ? max.size ? material ?

b, How many products do you need to coating per day ?

c, What material do you to coating on your products ? Any color requirements ?

- *Name

- *Title

- *Content